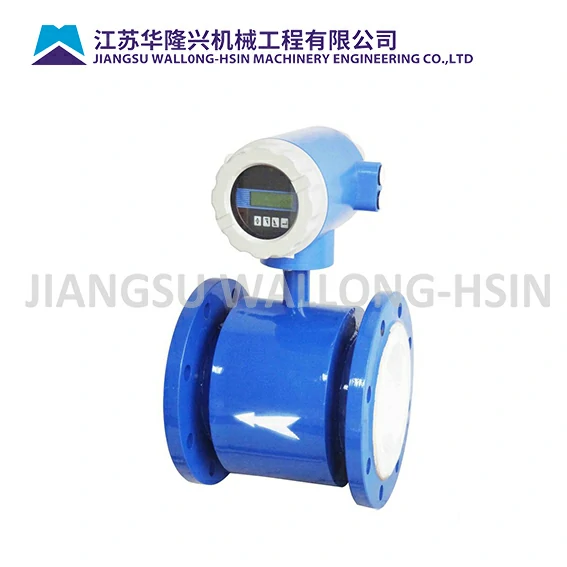

Electromagnetic Flowmeter

LDDC Series Electromagnetic Flowmeter is composed of sensor and converter. It works on Faraday’s Law of Electromagnetic Induction. It can measure the volume flow rate of liquid whose conductance is greater than 5μS/cm. It can not only measure the volume flow rate of general conducting liquid but also the corrosive liquids, such as strong acid, alkali, and two – phase (liquid – solid) suspensions such as mud, ore pulp, paper pulp, etc.

It is widely used in the fields of petroleum, chemical industry, metallurgy, textile, papermaking, environmental protection, food, municipal administration, irrigation project and river dredge, etc.

Operating Principle

According to Faraday’s Law of Electromagnetic Induction, a pair of measuring electrodes are installed on the tube wall which are perpendicular both to the measuring tube axis and the magnetic flux. When the conductive liquid moves along the tube axis, the conductive liquid cuts the magnetic flux and the induced voltage is produced. This induced voltage value is proportional to the flow rate, its value is:

E=KBṼD

E = KB\(\overline{V}\)D

E = Induced voltage

K = coefficient related to the distribution of magnetic field etc.

B = magnetic flux intensity

V= average flow velocity of conductive liquid

D = distance between electrodes, (inner diameter of tube)

The induced voltage E is regarded as the flow signal by the sensor and then transmitted to the converter. By amplifying, converting filter, and a series of digital processing, the instantaneous and cumulative flow rate can be displayed on the dot matrix LCD with backlight. The converter has 4 – 20mA output, upper/lower limit alarm and frequency outputs, and RS – 485 Communication connection HART protocol, etc.

Features

- There is no baffle inside the measuring tube. Its pressure loss is zero, and it is not easy to block.

- As long as the electrode and lining material are selected reasonably, the meter can meet the requirement of corrosion resistance and wear resistance.

- The measurement result has nothing to do with the liquid’s pressure, temperature, density, viscosity, conductivity (should be greater than the minimum conductivity) and other physical parameters, and would not be affected by the environment, thus the result is with high accuracy and stability and reliability.

- Using Modern analog signal conversion technology and high – performance large scale integrated chip to isolate, filter, amplify and process signals makes the measurement result more accurate.

- The parameters that affect the measurement results are automatically monitored and corrected, such as zero drift correction. As to the full range, the subsection flow coefficient setting and correction are used. Therefore, the measurement range is expanded, the intelligent degree and measurement accuracy are improved, and the stability performance is greatly improved.

- The meter has the function of power – off protection and over range alarm. The flow direction of the fluid inside the sensor can be set and therefore the installation of the sensor is not limited by the flow direction of the liquid, and the two – way flow measurement can be realized.

- Using double row dot matrix LCD with backlight to display instantaneous flow and cumulative flow at the same time, as well as the working status, parameters and measurement unit, etc.

- The meter has a wide range (maximum flow / minimum flow), normal application range is 20:1 and generally 30:1 or wider.

- The instrument configuration has a variety of output functions. It can match with computer and unit combination instrument, and can meet the requirements of printing, communication and networking.

Technical Parameters

| Conductivity of medium | >5μ S/cm. |

| Velocity | 0.3 – 12m/s |

| Flow range | Within the flow range, full scale flow can be programmable.

Details in the following table |

| Accuracy | Measured value ±0.5%,±1% |

| Environment condition | Ambient temperature

-10℃ – 50℃ |

| relative humidity

5% – 90% |

|

| Medium temperature | T₁≤65℃, T₂≤120℃, T₃≤180℃ |

| DN10 – 80:PN≤4MPa | |

| DN100 – 300:PN≤1.6MPa | |

| DN350 – 1000:PN≤1MPa | |

| Working pressure | Meter with higher pressure can be customized.

DN25 – 150,PN 10 Mpa, 16MPa, 26MPa are optional |

| Power supply | 220V AC 50Hz(90 – 245V AC 50Hz)

24V DC (20 – 36V DC) 3.6V battery power |

| Power consumption | 8W |

| Protection grade | Standard type IP65, special type IP67 or IP68 |

| Electrode material | 316L,HC,HB,Pt,Ti,Ta |

| Lining material | 1. NE 2.F46 3.PTFE

4.PFA 5.PUNE 6.CERAM |

Flow Table

| Diameter (mm) | Minimum Flow rate (m³/h) | Usual Full Scale Flow Rate (m³/h) |

| 4 | 0.01 | 0.05,0.1,0.2,0.25 |

| 10 | 0.10 | 0.4,0.5,0.6,0.8,1.0,1.6,2.0,2.5 |

| 15 | 0.20 | 1.0,1.2,1.6,2.0,3.0,4.0,5.0,6.0 |

| 20 | 0.35 | 2.0,2.5,3.0,4.0,5.0,6.0,8.0,10.0,12.0 |

| 25 | 0.55 | 3.0,4.0,5.0,6.0,8.0,10,12.0,14.0,16.0 |

| 32 | 1.0 | 5.0,6.0,8.0,10.0,12,16,20,25 |

| 40 | 1.5 | 8.0,10.0,12,16,20,25,30,40 |

| 50 | 2.5 | 12,16,20,25,30,40,50,60,70 |

| 65 | 4.0 | 20,25,30,40,50,60,80,100,120 |

| 80 | 5.5 | 25,30,40,50,60,80,100,120,160 |

| 100 | 8.5 | 40,50,60,80,100,120,160,200,250 |

| 125 | 14 | 60,80,100,120,160,200,250,300,400 |

| 150 | 20 | 100,120,160,200,250,300,400,500,600 |

| 200 | 35 | 160,200,250,300,400,500,600,800,1000 |

| 250 | 55 | 200,250,300,400,500,600,800,1000,1200,1600 |

| 300 | 80 | 300,400,500,600,800,1000,1200,1600,2000,2500 |

| 350 | 105 | 400,500,600,800,1000,1200,1600,2000,2500,3000 |

| 400 | 135 | 500,600,800,1000,1200,1600,2000,2500,3000,4000 |

| 450 | 175 | 600,800,1000,1200,1600,2000,2500,3000,4000 |

| 500 | 215 | 800,1000,1200,1600,2000,2500,3000,4000,5000,6000 |

| 600 | 305 | 1000,1200,1600,2000,2500,3000,4000,5000,6000,10000 |

| 700 | 415 | 1200,1600,2000,2500,3000,4000,5000,6000,10000,12000 |

| 800 | 545 | 1600,2000,2500,3000,4000,5000,6000,10000,12000,16000 |

| 900 | 690 | 2000,2500,3000,4000,5000,6000,10000,12000,16000,20000 |

| 1000 | 850 | 2500,3000,4000,5000,6000,10000,12000,16000,20000,25000 |