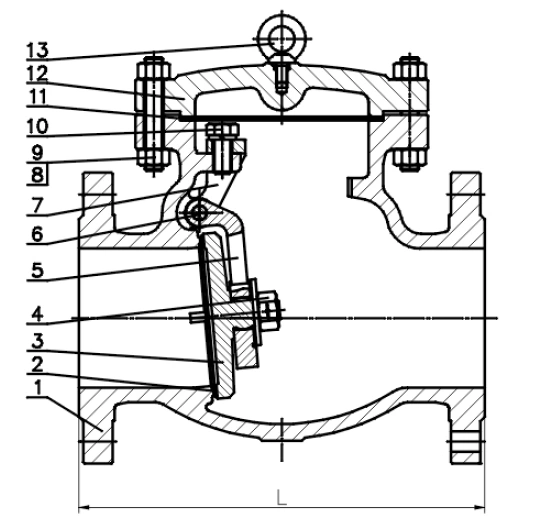

API Swing Check Valve

STANDARDS

Design and Manufacture:BS 1868~1873,ASME B16.34

Inspect and Test:API598

Butt-weldingEnds:ASME B16.25

RFFlanged Ends:ASME B16.5,B16.47

Face to Face:ASME B16.10

Bolted Bonnet, Swing and lift disc; Metallic seating surfaces.Bolted cover and pressure seal cover swing and lift disc.

Body and Bonnet Connection

The body and bonnet of Class 15o-Class90o check valves are usually with studs and nuts.And the body and bonnet of Class 150o-Class2500 check valves are usually of pressurized seal design

Gasket

Stainless steel + flexible graphite wounded gasketis used for Class150 and Class30o check valve; Stainless steel + flexible graphite wounded gasket is used for Class60o check valve, and joint gasket is also optional for Class60o check valve; Ring joint gasketis used for Class9oo check valve; Pressurized seal design is used for Class 15oo-Class250o check valves.

Seat

Thesealingsurfaceof theseat is spraywelded with hard alloyspecified by the customer. For stainless steel checkvalve,integralseat is usually adopted,or to weld hard alloydirectly integrally.request about Iheseat, please kindly advise before placing theorder.